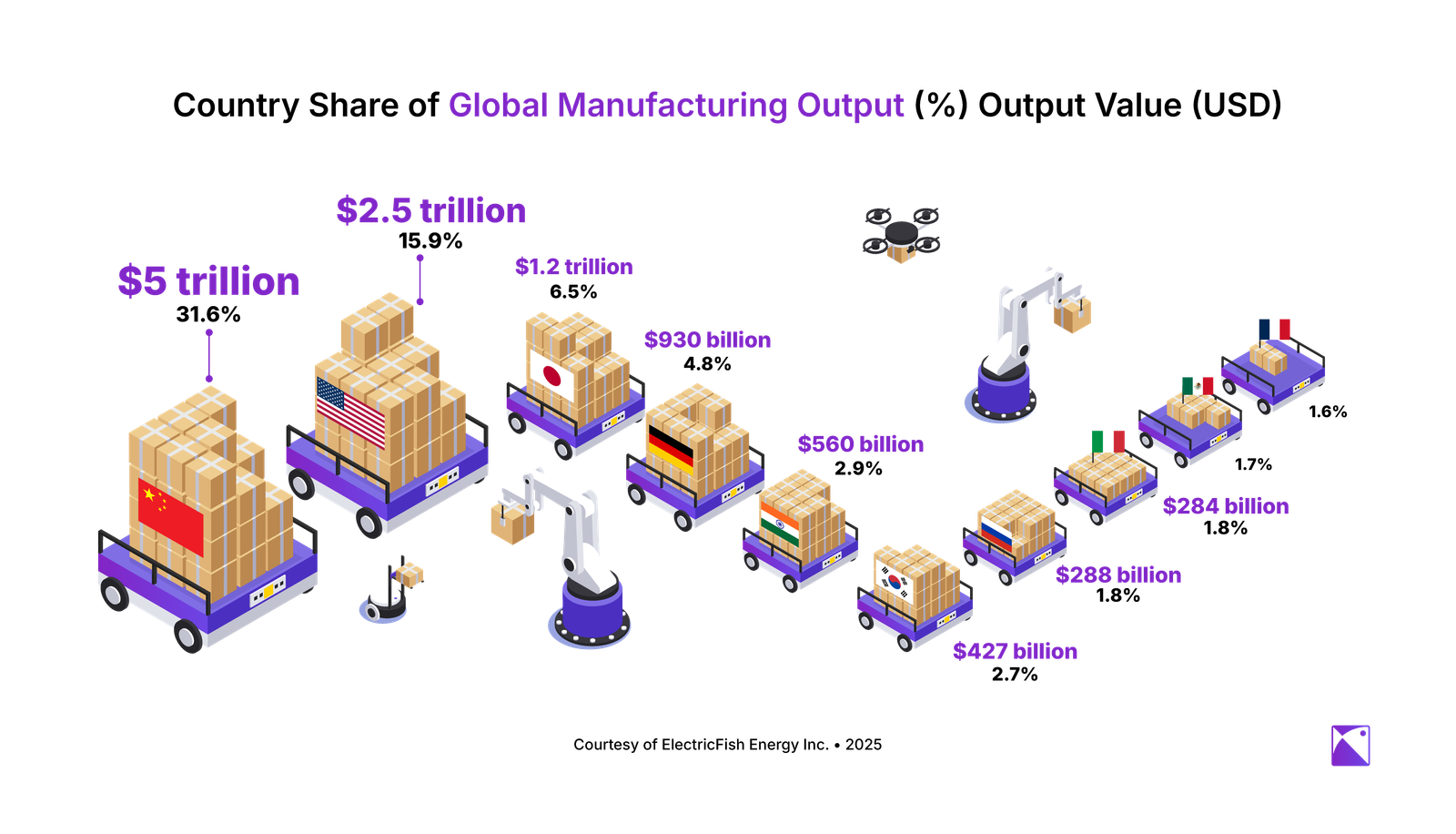

The U.S. is a global leader in clean tech innovation—home to 24% of the world’s top clean tech innovation ecosystem. Yet, we contribute only 10% to global clean tech manufacturing. Meanwhile, China dominates with 60% of global clean tech production, despite owning just 20% of the top clean tech companies.

This gap presents both a challenge and an opportunity: How do we turn more of our world-class innovation into high-quality, American-made products that power the clean energy transition?

- Rebuilding Manufacturing Infrastructure- Much of the U.S.’s manufacturing capacity was developed in the mid-20th century and needs modernization. Investing in next-gen factories, automation, and smart manufacturing can help revitalize the sector.

- Strengthening the Workforce Pipeline- As industries evolve, so must our workforce. Investing in skilled trades, apprenticeships, and training programs will empower American workers and create high-paying, future-proof jobs in clean tech manufacturing.

- Competing on Value, Not Just Cost- While labor costs may be lower in some regions abroad, U.S. manufacturing delivers unmatched quality, safety, and innovation. With robotic automation and Industry 4.0 technologies, we can boost efficiency while keeping jobs here at home.

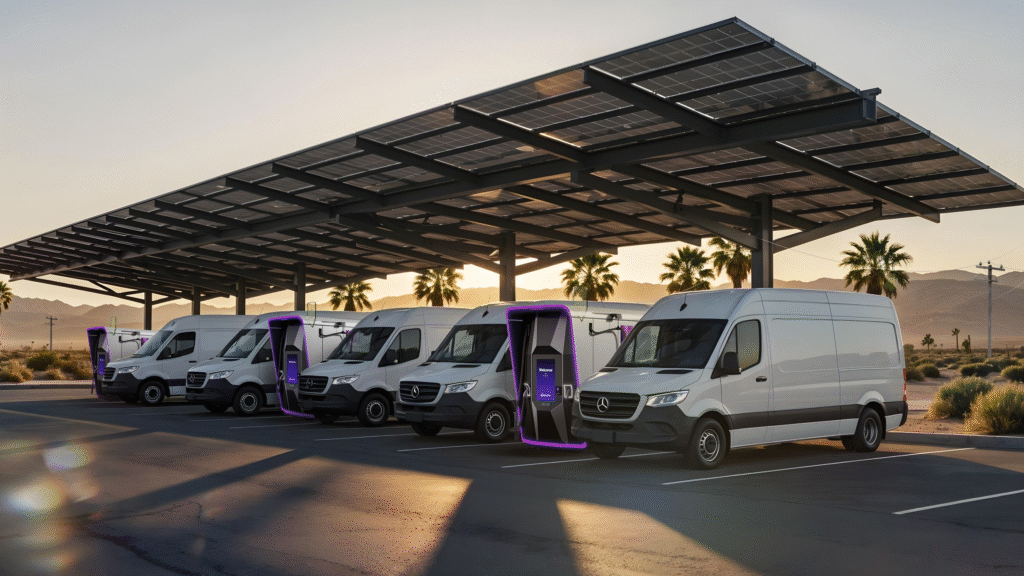

- Resilient, Sustainable Supply Chains – Over-reliance on global supply chains has made us vulnerable to disruptions. Strengthening domestic suppliers, investing in local materials, and leveraging federal incentives can make the U.S. a leader in clean tech production.

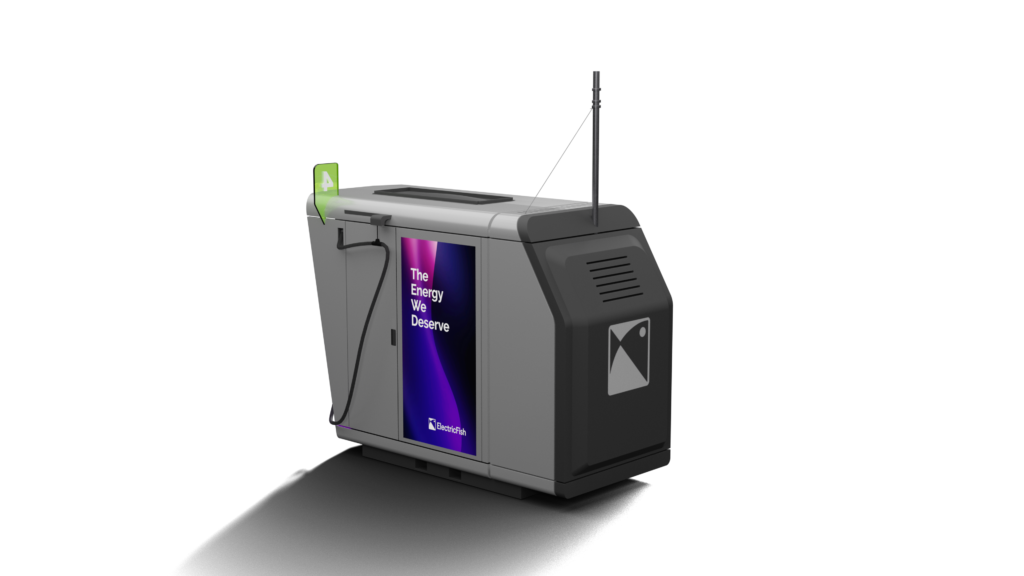

Why, at ElectricFish, we are manufacturing domestically:

- Aligned with Mission: Overseas shipping and supply chain dependency increase carbon emissions. Domestic manufacturing helps reduce our environmental footprint and supports sustainability efforts.

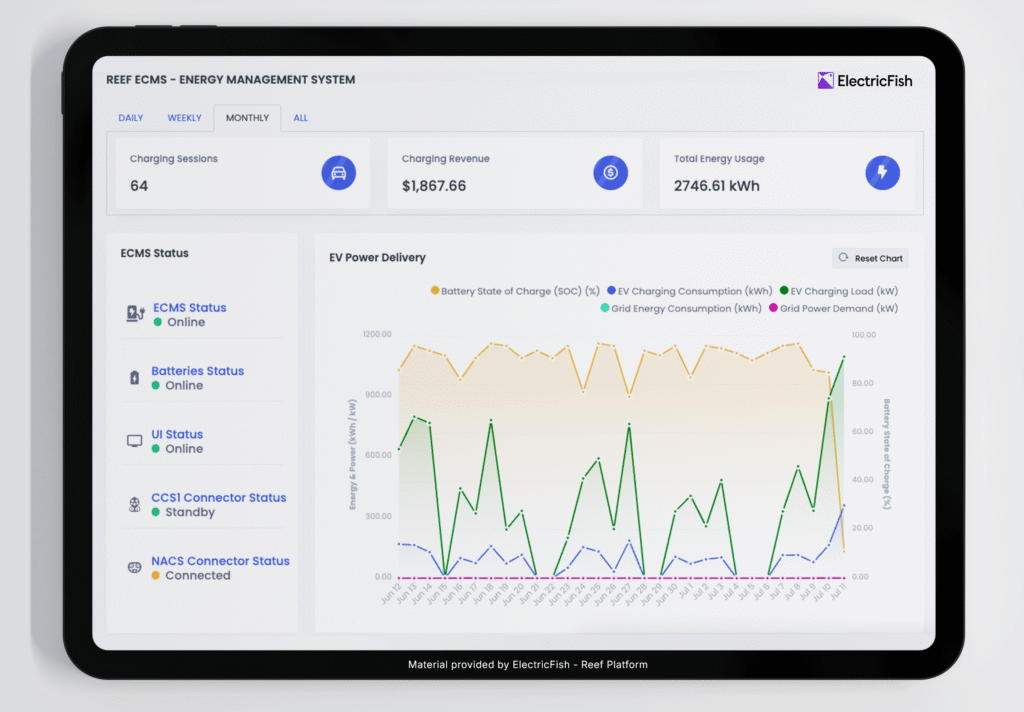

- Accelerated Innovation with a Feedback Loop: Proximity to manufacturing facilities means faster, more direct collaboration with R&D teams. This real-time feedback leads to continuous product improvements, enabling quicker problem-solving and innovation.

- Upfront Cost Isn’t Everything: The initial low cost of overseas manufacturing can be tempting, but it’s often cheaper in the long term to replace faulty parts than to maintain them. Complex global supply chains create delays and make quality control harder, which can ultimately drive up costs.

- Vulnerability to Global Shocks: The COVID-19 pandemic revealed the vulnerability of global supply chains, affecting industries worldwide—including ours. We saw firsthand how reliance on overseas production created disruptions and delays. While the growing awareness of these vulnerabilities is encouraging, transitioning to more resilient, domestic manufacturing requires significant effort and investment.

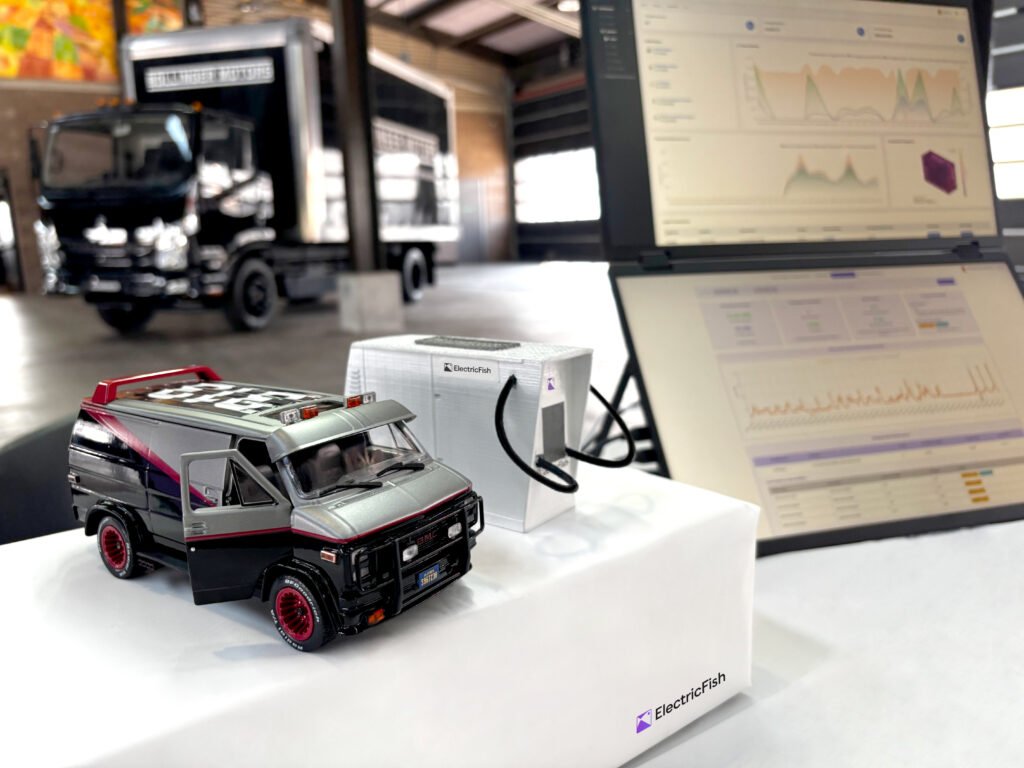

At ElectricFish, we believe in reshoring clean tech manufacturing to the U.S. More than 60% of our bill of materials (BOM) is domestically manufactured, and we make conscious decisions to purchase from Build America Buy America(BABA) authorized vendors whenever possible.

How Do We Keep Costs Down?

- Tax Incentives Help: Support from federal and state programs boosts domestic production.

- DFM/DFA Practices: As a recipient of the California Energy Commission’s RAMP grant, we are designing for manufacturing and assembly to make production more cost-effective.

- Sustainable, Local Supply Chains: Reducing emissions and costs by minimizing overseas dependencies.

- Investing in robotic automation and actively adopting Industry 4.0 techniques, to build the right foundation for a scalable , efficient clean energy manufacturing system. More to come on this!

The Future of Clean Tech Manufacturing

The U.S. leads the world in clean tech research and development. Now, we must turn that innovation into large-scale production to drive economic growth, energy security, and job creation.

This transition is already happening. Industry, labor leaders, policymakers, and startups like ElectricFish are working together to strengthen domestic manufacturing, invest in workforce development, and modernize supply chains.